Feed efficiency imperative against inflation

Protecting profitability is a major concern shared by dairy farmers worldwide. Inflation has been running at over 5% since the end of 2021 for almost all countries, according to IFCN. In addition to the feed cost increase, other production costs have almost doubled. Compounding this are adverse weather conditions globally, environmental constraints, new animal welfare requirements, new regulations and laws and, last but not least, a poor social image of farmers.

Given the uncertain economic outlook, minimising the costs associated with milk production has never been of greater importance. Confronted with this reality, individual farmers react differently, but ultimately there are only 2 ways to face the situation: suffer the price variations and try to stay in business by taking short-term measures, or work towards a target milk price to determine an attainable maximum production cost and then take a pragmatic approach to precisely identifying the various components of this cost.

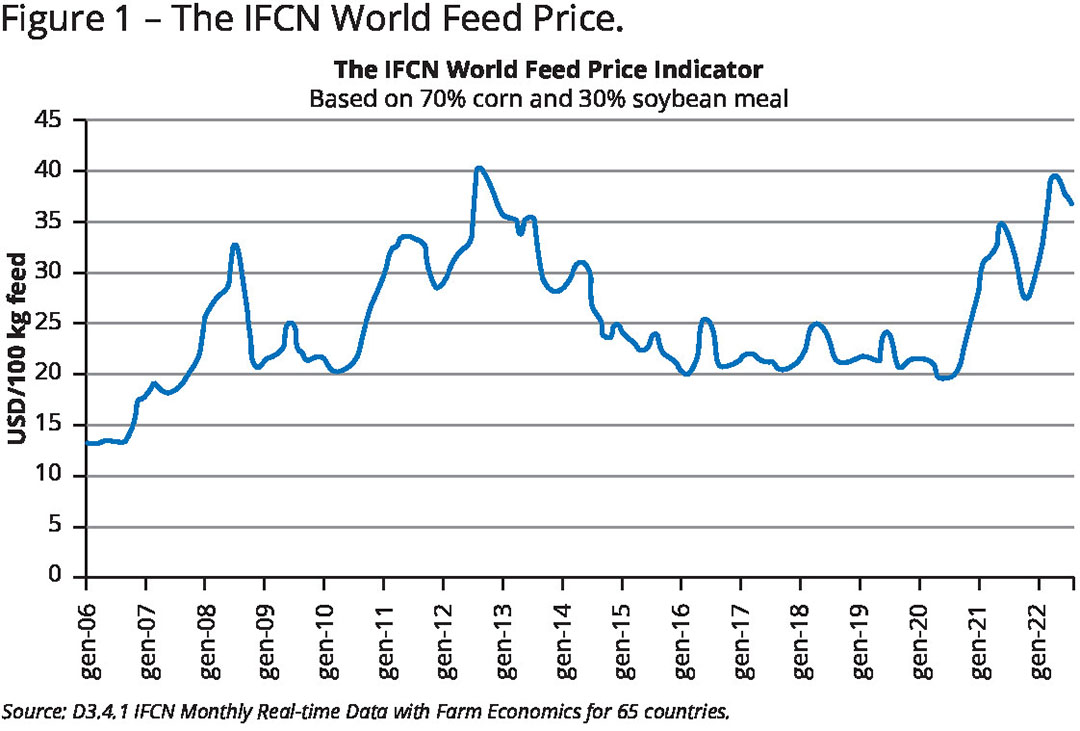

The former option often leads to drastic decisions with potentially long-term negative impacts. The latter, however, allows farmers to identify which aspects of production they can control to keep their production costs aligned with milk prices. This approach requires a serious commitment to collecting reliable data and processing and responding to insights. Against a backdrop of rising global milk prices and escalating feed costs (see Figure 1), this approach makes the most economic sense.

The former option often leads to drastic decisions with potentially long-term negative impacts. The latter, however, allows farmers to identify which aspects of production they can control to keep their production costs aligned with milk prices. This approach requires a serious commitment to collecting reliable data and processing and responding to insights. Against a backdrop of rising global milk prices and escalating feed costs (see Figure 1), this approach makes the most economic sense.

As always, the first step in taking control of any parameter is to monitor it. For dairy farmers, this means being aware of production cost components to act on them.

However, this is far from being the only area to consider. Other global factors, such as lactation performance over a lifetime or milk production per day of life, provide excellent opportunities for significantly reducing the fixed costs per litre of milk. Reaching this goal requires increasing productivity and longevity and/or reducing unproductive periods, such as heifer rearing.

Maximising efficiency

For example, take a cow from an average herd that started milk production at 26 months of age, producing 8,000 kg per 305 days of lactation with 60 days of dry period, and which was culled after 2.4 lactations. This cow produced 19,200 litres over her lifetime but only 11.7 litres per day of life. If nutritional management can reduce the age at first calving to 24 months, this will increase milk production per day of life to 12.2 litres per day. At the same time, heifer production cost is reduced by approximately € 70 per animal, which is equivalent to a reduced production cost of € 3.65 per 1,000 litres. Using a similar approach, increasing feed efficiency by 5% would also increase milk production over a lifetime by 960 kg, thus increasing the milk production per day of life to 12.4 litres.

Looking at these figures, it is obvious that the goal of the dairy operation should be to maximise the efficiency of converting feed into milk. Because feed efficiency variation factors in dairy herds are numerous (days in milk, body weight change, milk composition, herd management, feed digestibility, heat stress or activity, etc.), the next question for farmers is how to influence this crucial parameter. While farmers have little impact on the lactation stage and heat stress, and can only make moderate changes regarding herd management, nutritional management actions that result in increased feed digestibility can easily be implemented.

How efficiently feed is converted into milk is determined by 3 major factors:

- The digestibility of the feed, which is linked to diet balance, ingredient characteristics, physical aspects, harvesting conditions, etc.;

- A highly active population of rumen micro-organisms to increase the overall effectiveness of rumen fermentation; and

- An adequate, stable rumen environment, promoting microflora development.

In terms of the rumen microflora population, the most sensitive one is the fibre degrader as it requires specific nutrients to grow and function at its optimal activity level. In particular, this rumen bacteria group has a specific requirement for non-protein nitrogen (NPN) and ammonia as a nitrogen source, while it rather inefficiently uses more complex protein sources as a substrate.

However, common NPN sources such as urea or vinasses are rapidly degraded into ammonia (NH3) in the rumen environment, evident in their complete disappearance after 15 minutes following ingestion. Being potentially toxic, ammonia is quickly absorbed into the bloodstream and converted in the liver into urea. A minor proportion of this is recycled, and a larger proportion is excreted in the urine. As a result of this process, fibre-digesting bacteria in the rumen have access to adequate ammonia levels for a very limited amount of time and can experience, on the same day, periods of excess where urea is produced and periods of deficit where the activity of cellulolytic rumen bacteria is reduced. This, in turn, reduces fibre degradation.

Using an alternative nitrogen-rich feed ingredient such as Optigen (Alltech Inc.) takes advantage of a constant release of NPN in the rumen environment, ensuring a steadier ammonia concentration in the rumen and providing ideal conditions for the growth of fibre degraders and, ultimately, fibre digestion. Also, using Optigen provides a similar quantity of protein equivalent in a more concentrated way than common vegetable protein sources, which allows nutritionists to include a higher quantity of other feed ingredients such as forage or energy sources, which are often time-limiting in high-yielding dairy cow diets. As a result, more rumen-friendly diets can be fed, translating at farm level into fewer particles left undigested in the manure. This has a direct impact on how feed is converted efficiently into milk.

In a university trial carried out at Harper Adams University in the UK, Optigen inclusion in dairy cow diets at 120 g/head/day resulted in an improved feed efficiency of 1.44-1.51 litres of fat-corrected milk per kilogrammes of dry matter intake (DMI). Other dietary changes consisted of increasing forage quantity while being able to reduce vegetable protein supply by 1 kg/head/day.

Besides adequately feeding the rumen microflora and the cellulolytic population, other dietary manipulations have been investigated, including the use of live yeasts to stimulate specific rumen bacteria activity. Yea-Sacc (Alltech Inc.) has consistently demonstrated its beneficial effect on stimulating specific groups of rumen bacteria such as fibre degraders and lactic acid utilisers. More recently, a meta-analysis (Salami, S.A. et al.; European Federation of Animal Science, 2022) based on 52 trials conducted in beef cattle across 12 countries from 1990 to 2019 showed that Yea-Sacc increases fibre digestion (+9.2%); maximises rumen fermentation by increasing the production of volatile fatty acids (+5.3%) and microbial cell yield (+3.0%); and improves the growth rate (+5.2%), feed efficiency (+3.5%), carcass weight (+1.1%) and dressing percentage (+0.6%) of beef cattle.

Conclusions

As feed costs rise, feed efficiency becomes one of the key economical drivers that farmers must monitor closely. Together with adequate diet formulation and good management practices, Optigen and Yea-Sacc have consistently demonstrated beneficial effects on milk production and a high feed conversion efficiency, supporting dairy farmers to better control milk production costs.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.