From rumen to revenue: Optimising dairy cow nutrition

In today’s dairy industry, where feed prices are volatile and margins are often slim, efficiency is not a luxury: it is a necessity. Farmers are under increasing pressure to produce more milk from fewer inputs, all while navigating labour shortages, tightening regulations, and rising expectations around animal welfare and environmental sustainability.

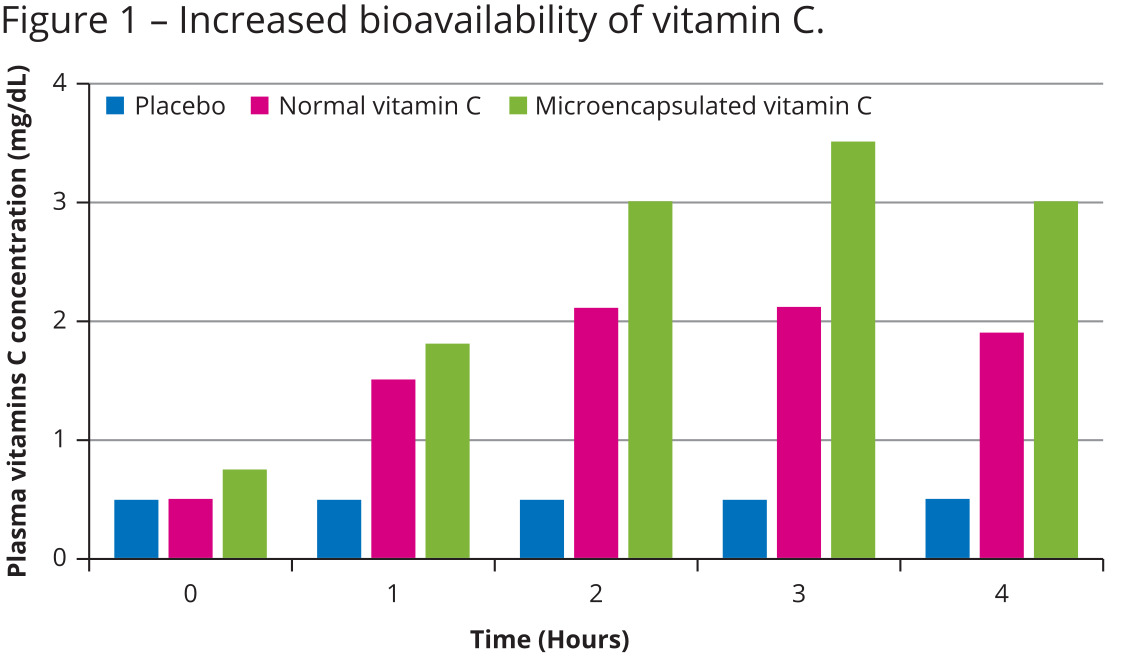

Microencapsulation, the practice of encasing active ingredients in a protective barrier, is changing how dairy cows absorb and utilise nutrients. While not new to the cattle industry, its application in animal feed has grown exponentially in recent years, particularly in high-performance rations for lactating cows. The reason is simple: what goes into a cow’s mouth is only part of the story. What survives the cow’s rumen, reaches the bloodstream, and actually fuels production – that is where the real value lies.

The rumen – the cow’s first and largest stomach compartment – is a hostile environment for sensitive nutrients. Vitamins, probiotics, enzymes and amino acids are often degraded by ruminal microbes, high pH, or the heat generated during feed processing. However, with microencapsulation, nutrients are sealed within a thin, food-grade membrane that protects them from degradation in the rumen and delivers them where they are most needed – often in the small intestine. This delayed, site-specific release maximises bioavailability, meaning the animal gains more benefit from every gram of feed.

Turning feed into fuel

One of the most significant benefits of this technology is its impact on nutrient efficiency and digestion. By protecting fibrolytic enzymes, for example, microencapsulation can enhance fibre breakdown in the feed. That is no small advantage – when cows are able to extract more energy from roughage, producers can reduce the dose of expensive concentrate feed without compromising yield.

Similarly, encapsulated vitamins and trace minerals are more likely to reach their absorption sites intact, supporting everything from immune function to reproductive health. For dairy operations seeking to reduce their reliance on antibiotic interventions, this level of nutritional precision is increasingly becoming indispensable.

However, the advantages of microencapsulation are not limited to digestion – they also extend to disease prevention and overall cow health. Take probiotics: while unprotected strains often fail to survive passage through the rumen, encapsulated probiotics can reach the hindgut intact, where they help regulate intestinal flora. A stable gut microbiome enhances nutrient absorption, suppresses pathogenic bacteria, and has been linked to improved milk quality. Antioxidants such as vitamin C, when protected from early degradation, help counter oxidative stress during the most vulnerable stages of a cow’s lifecycle – particularly pre-calving and early lactation. This can result in better recovery after calving and healthier, more vigorous calves and cows.

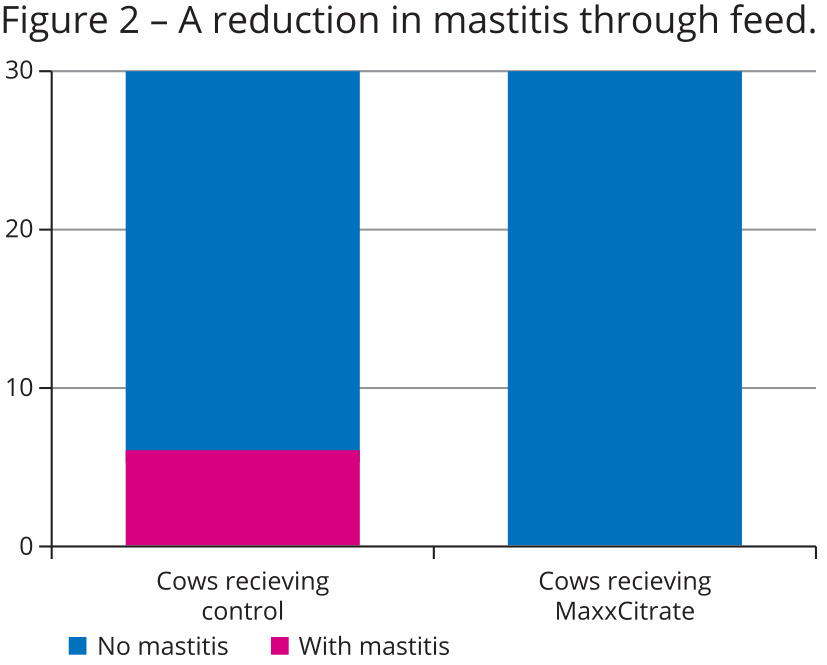

Mastitis, meet your match

Perhaps the most compelling case for microencapsulation lies in its potential to prevent common health problems that can erode profitability. In a recent study we conducted, dairy cows receiving feed containing a slow-release form of trisodium citrate dihydrate showed no cases of mastitis, compared to a 20% incidence rate in a control group. The encapsulated compound helped reduce milk conductivity, lower inflammation, and maintain udder health.

These outcomes do not just affect animal well-being – they have a direct and measurable impact on yield, culling rates and veterinary costs.

The economics are equally compelling. With protected nutrients reaching their targets more efficiently, producers can achieve the same – or improved – results with lower inclusion rates. That translates to less waste, reduced over-formulation and stronger returns on investment – especially important when ingredient costs are rising and market prices are unpredictable. It marks a shift from volume to value: less feed delivering more milk by weight.

The economics are equally compelling. With protected nutrients reaching their targets more efficiently, producers can achieve the same – or improved – results with lower inclusion rates. That translates to less waste, reduced over-formulation and stronger returns on investment – especially important when ingredient costs are rising and market prices are unpredictable. It marks a shift from volume to value: less feed delivering more milk by weight.Microencapsulation also opens the door for functional additives that would otherwise be impractical. Compounds with strong odours, unpleasant tastes or poor stability during processing can now be incorporated into feed without compromising palatability or shelf life. And because these nutrients are released gradually, they help prevent the metabolic spikes and crashes associated with conventional supplementation.

A more sustainable dairy model

As the industry moves toward more sustainable production practices, microencapsulation offers a pathway to reducing environmental impact without sacrificing performance. Improved feed conversion means fewer resources are required to produce the same amount of milk, while a lower incidence of disease reduces the need for medical interventions and the associated risks of antimicrobial resistance.

Of course, like any technology, the success of microencapsulation depends on how it’s applied. Not all encapsulates are created equal, and the delivery system must be tailored to the specific nutrient, the cow’s physiological stage and the farm’s broader nutrition strategy. But when formulated correctly, these tiny particles deliver oversized benefits – translating breakthrough science into real-world results.

In fact, what makes this technology particularly compelling is its practicality. It enhances the effectiveness of existing ingredients, aligning with the demands of herd management rather than disrupting them. In an industry where complexity often hinders implementation, such seamless integration is no small feat.

Ultimately, microencapsulation does not just change what is in the feed bunk – it changes the economics. It shifts the equation from feeding cows more to feeding them more precisely. It is a tool for producers who believe that precision pays – and who are ready to capture more value from every drop of milk.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.