Gold and silver medals for the dairy industry at EuroTier 2024

Innovation winners have been announced! EuroTier 2024 awarded dairy innovations gold medals and silver medals. Prof Heinz Bernhardt of the EuroTier Innovation Commission pointed to various trends, including AI in animal farming, animal welfare, robotics, emission reduction and barn climate improvement. The 2024 edition of EuroTier will be held in Hanover, Germany, from 12-15 November, showcasing the winning innovations below.

Avoid heat stress

Avoid heat stress

Cow-Welfare A/S

Hall 12, B49

With Flex Air Stall, the cow’s comfort is significantly increased by a constant flow of fresh air into the lying area via the cubicle bar. Animal suffering due to heat is therefore quickly and continuously prevented. The system creates a comfortable climate zone in the animals’ resting area and ensures optimum cow welfare in the freestall barn. The Flex Air Stall thus serves to directly protect the welfare and health of cows.

AI system to manage calves

Förster-Technik

Hall 13, D35

CalfGPT from Förster-Technik enables voice-controlled, AI-aided data management for the care of calves for the first time. The CalfGPT management tool is based on the leading AI system from OpenAI. It enables the farmer to submit freely formulated enquiries concerning the general situation or individual calves using a voice connection via the farm’s own WiFi and to receive specific information about the calves and alarms on a mobile phone or tablet. Pre-formulated commands are not necessary; new information on individual calves can also be sent directly and verbally to CalfGPT for further documentation. Users can additionally obtain a specific digital overview of calf groups.

Improved rumen function

Zinpro

Hall 22, C31

ZinproIsoFerm is a blend of volatile fatty acids. Their targeted supplementation offers the potential to improve microbial protein synthesis and fibre digestibility, thus fostering rumen function, metabolism and efficiency.

Fibre digestion is increased by up to 15% and microbial protein synthesis by up to 6%. New, preliminary test results additionally indicate their potential to reduce methane production. The addition of Zinpro IsoFerm can lead to a higher milk yield during early lactation or better lactation curve persistence during late lactation.

High-pressure cleaner

Aufratech

Hall 24, A23

The Exon Dual and the Exon Mini have been developed to reduce physical stress during high-pressure cleaning. A lightweight, adjustable and comfortable tubular chassis and corresponding harnesses result in significant advantages in distributing the weight of the lance over the shoulders. It is also possible to attach the supply hose to the waist area. A 2-hand control module, permanently positioned in front of the user, results in a low trigger force. Vibrations are also reduced and work productivity is improved.

Optimum use of space cow housing

Spinder Dairy Housing Concepts

Hall 12, D03

With Spinder Track, the usable housing area can be adapted to the corresponding group size at any time by means of a gate that runs on rails. The system is designed so that it can be operated and locked in the desired position by one person, enabling optimum use of space. Animals or people can pass through an integrated sliding gate at any time. The system can be installed in newly-constructed barns and retrofitted in existing barns and is adapted to the respective specifications of the barn. This results in hardly any interference with other work in the barn, particularly due to the height of the rail.

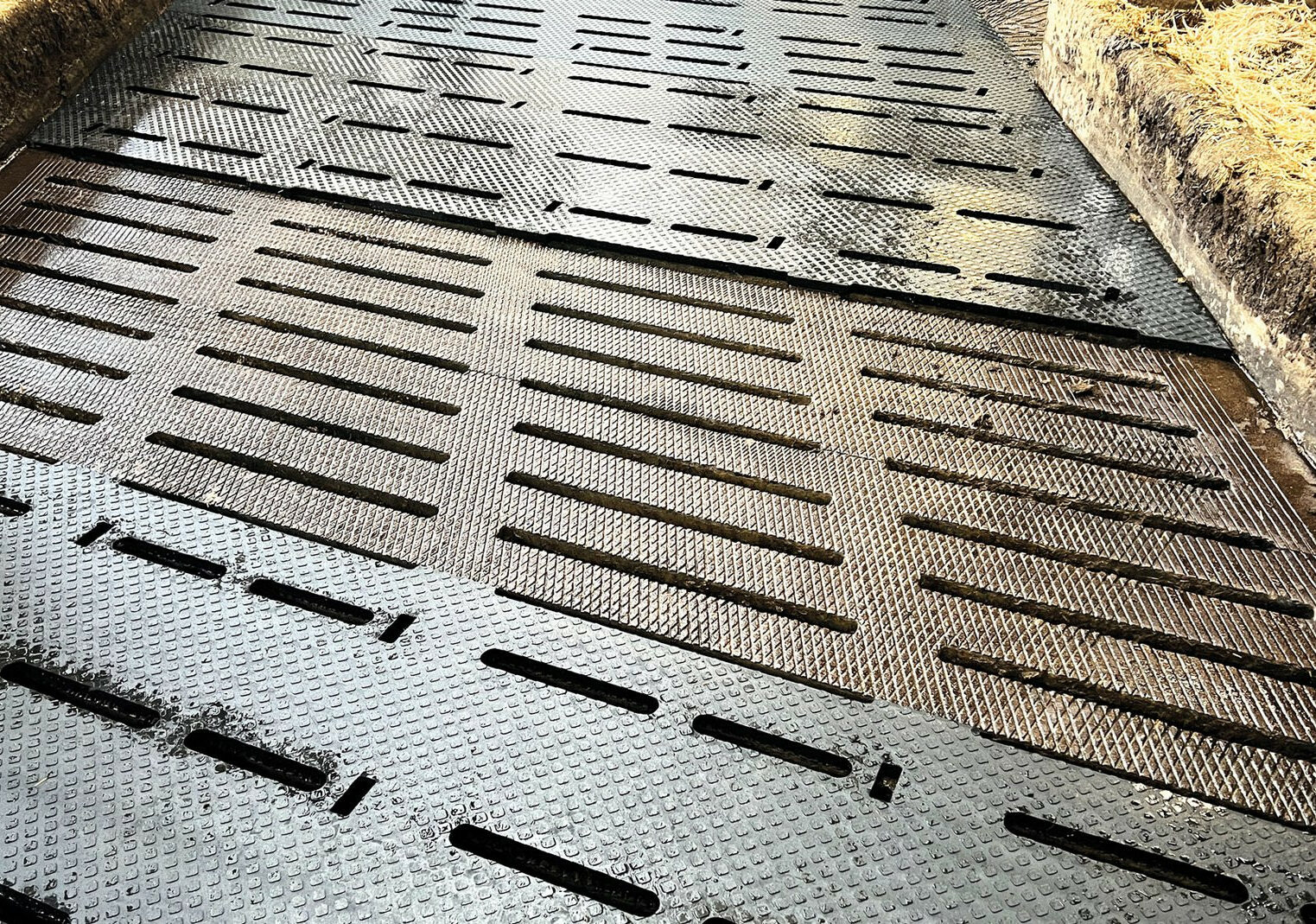

Better hoof health and lower emissions

Gummiwerk Kraiburg

Hall 12, E57

Gummiwerk Kraiburg has developed the espaFLEX for new and existing slatted floor surfaces. The espaFLEX has a special corrugated profile with a 3% gradient structure transverse to the walking direction. The 3% gradient enables urine to flow rapidly through the slots, resulting in a quickly drying floor. The improved dryness of the floor surface ensures drier hooves for better hoof health. Due to the quick drainage of urine, in combination with manure-collecting robots, lower ammonia emissions are to be anticipated.

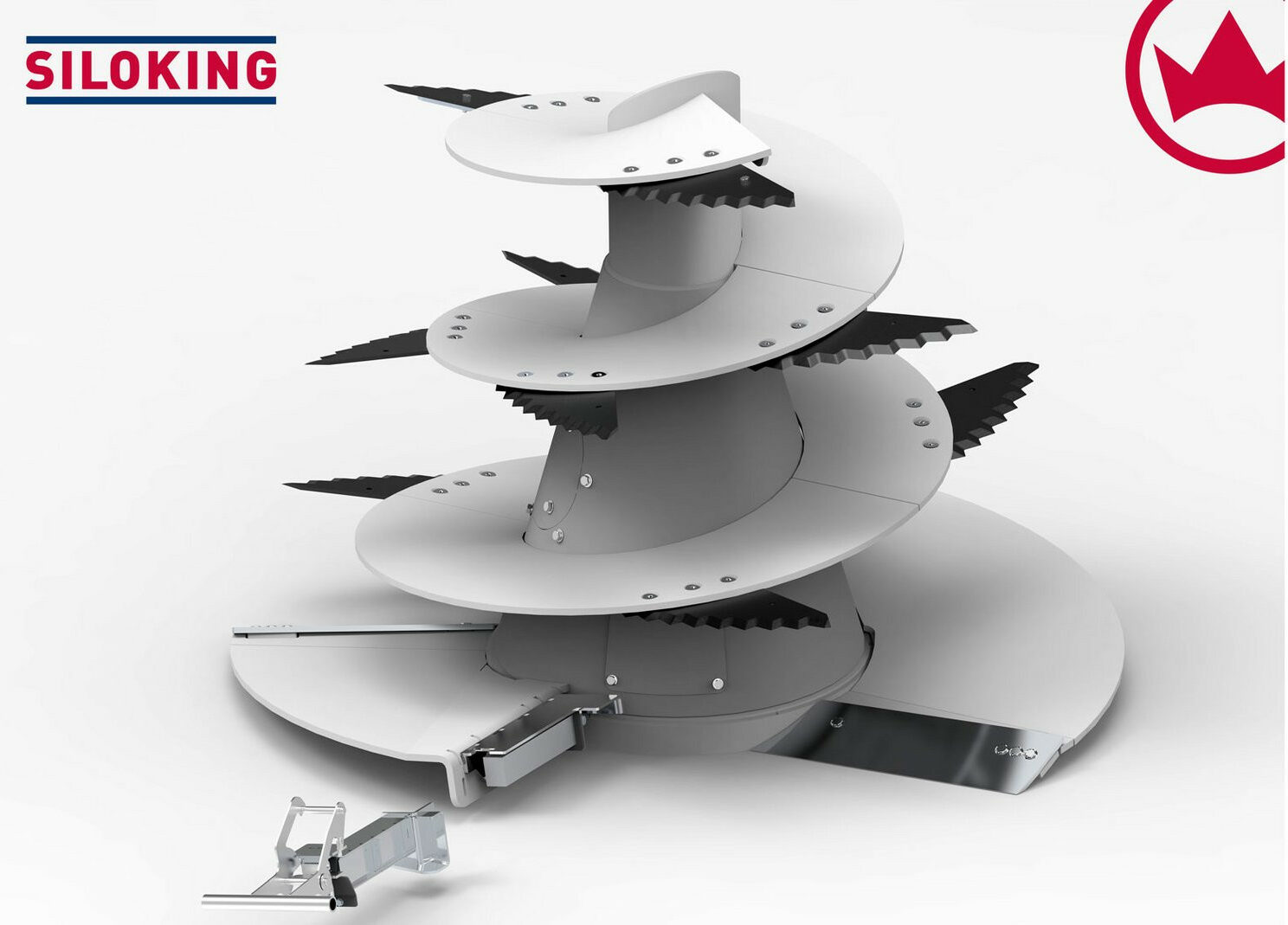

Reduce risk of injury

Siloking Mayer Maschinenbau GmbH

Hall 27, E15

In mechanised cattle feeding, foreign bodies containing iron in the mixed ration pose a significant risk. To counter this problem, permanent magnets, to which these magnetisable foreign bodies adhere, have been installed in feed mixing systems. To date, however, the adhering foreign bodies must be manually removed individually from the integrated magnets. Now, the heavy-duty magnet can now be removed together with its surrounding housing and all adhering foreign bodies. This shifts the activity of detaching them from the principal danger zone, significantly reducing the risk of injury.

Improving calf welfare

Urban

Hall 13, B09

Urban SipControl is an innovative system for determining the welfare of suckling calves at automatic feeders. The system records the animal’s sucking strength and the individual swallowing processes during the drinking process in high resolution and can adapt the feeding process to the individual animal by means of active flow control. Physiologically optimised feeding times in combination with low swallowing volumes can therefore be implemented for each individual animal during each drinking process. Deviations from the animals’ individual sucking patterns can be used for predictive health monitoring.

Better calf feeding hygiene

Hiko

Hall 11, D59

Open feeding buckets significantly facilitates the entry of dirt and flies. Hiko offers a practical solution in the form of the Easyfill feeding bucket lid, which is equipped with a self-closing opening through which the filler neck of the milk shuttle can be inserted at any time and the bucket filled. As handling barely differs from filling without a lid, a high level of staff acceptance is to be anticipated. The Easyfill feeding bucket lid therefore ensures that the feeding buckets remain tightly closed, thereby extensively preventing the entry of dirt or flies.

Bale twine remover

Betebe

Hall 12, F26

The Betebe straw express enables the automatic removal of the bale strapping from the straw bales for the first time, thereby minimising the susceptibility of littering systems for cubicle, sloping floor or deep litter sheds to errors. This automatic baler twine removal makes it possible to store up to 12 bales of straw in a space-saving, vertical bale magazine. In combination with the littering system, the system can litter fully automatically and also reduce dust development in the shed to a minimum. The space-saving system can be installed in new barns and retrofitted.

Reducing ammonia emissions

SKW Stickstoffwerke Piesteritz

Hall 12, F23

The Atmowell technology with urease inhibitor from SKW and Betebe is a combination of various technologies. SKW Stickstoffwerke Piesteritz, together with Betebe, offers a practical system that enables ammonia emissions in cattle barns to be significantly reduced at the point of origin, i.e., in the animals’ walking area. Reducing barn-specific NH3 emissions and thus undesirable nitrogen inputs into nitrogen-sensitive ecosystems in new barn construction situations and for retrofitting in existing barns. A combination of various technologies equates to a significant improvement that promises economic benefits and makes environmental targets for reducing NH3 emissions achievable.

Holistic system for rodent control

MS Schippers

Hall 11, A11

HyCare Digital from MS Schippers is a holistic system for rodent control on farms without the use of rodenticides. This system combines natural methods of rodent deterrence, such as the colonisation of predators and habitat management, with digital surveillance and trap systems. The individual surveillance points and traps can be monitored via an app, which reports observations directly to the farmer’s smartphone. The triggering of traps is also reported so that they can be quickly checked and reactivated. The control measures are also documented at the same time.

Calf ear sensor to improve predictions

CowManager

Hall 11, F55

Health monitoring for calves is presented for the first time with the ear sensor from CowManager. The algorithm uses machine learning methods to do this and therefore makes it possible to display constantly improving predictions regarding the state of the health of individual calves. The alarms are adapted to the age of the animals. Diseases are recognised as early as possible, treatments are documented and health is continuously monitored from calf to cow. CowManager-Youngstock can reduce antibiotic consumption and further optimise animal health.

Ear tag sensor for better calf monitoring

MSD Tiergesundheit

Hall 11, B10

The SenseHub Dairy Youngstock ear tag sensor enables automated round-the-clock behaviour monitoring for calves and young cattle during the first 12 months of their lives. Behavioural parameters such as activity, suckling, feeding and rumination are recorded via the electronic ear tag and can be linked to the farm’s herd management system. This enables possible health problems to be recognised early on and the data can also be shared with the herd veterinarian or advisors. It improves animal welfare and can reduce the use of antibiotics.

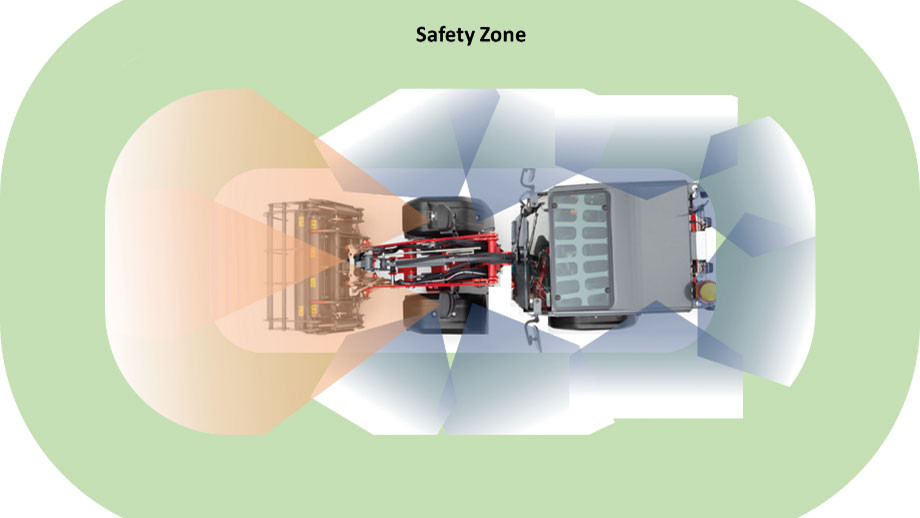

Reducing the risk of accidents

Weidemann

Hall 27, C24

Constantly climbing on and off is typical for working with a wheel loader and is not only strenuous, but also poses a constant risk of injuries. Activities in which the operator switches between moving the working machine forwards and another job are particularly frequent in the case of yard and wheel loaders. The ‘follow me’ assistance system makes this work with the Hoftrac considerably easier. The ‘follow me’ function enables the operator to descend from the vehicle and have the Hoftrac follow them autonomously to the location of the next job. The operator can command the Hoftrac to follow with a hand-held device and fix it in position at the destination, after which it can follow on again to the next point. In this process, a button has to be continuously pressed due to safety reasons. A virtual safety zone is established around the machine, which ensures that the operator and the area around the machine are protected.