Key components of a mycotoxin risk management programme

An effective mycotoxin risk management programme must integrate multiple touchpoints – from crops in the field through harvesting, raw material storage, feed mill hygiene, data analysis and the use of mycotoxin binders.

As toxic chemicals produced from moulds, mycotoxins present a persistent and far-ranging threat. Mycotoxins can grow on crops in the field, or emerge during harvesting, transport of raw materials (RM) or in the storage of RM in silos, rooms, or bags. Mould and mycotoxin growth can continue during feed production, storage at the mill, and during transport to farms. On the farm, moulds and mycotoxins can grow in feed silos and feed troughs, threatening animal health and performance.

Multiple factors including the animal species in question, amount of toxin consumed by an animal, type and number of mycotoxins in the feed, animal age and sex, and the duration of toxin exposure can influence the extent of toxicity in the animals. Such a complex challenge demands an integrated approach as even one overlooked factor can hinder mycotoxin control efforts.

Although not all mycotoxins pose a risk to human health, Trouw Nutrition follows a stringent hazard analysis critical control point (HACCP) approach to manage mycotoxin risk. Some essential components of this protocol are described here.

Crop management

Crop management is step one in an effective mycotoxin management strategy. Mycotoxigenic and pathogenic fungi invade plants from the soil. Suitable agroclimatic conditions will trigger mycotoxin production in plants and subsequent distribution of the mycotoxins in various plant parts, including the grains. Non-pathogenic fungi will also invade plants via wounds and damage caused by invading plant pests.

Farm management practices to counter these risks include proper ploughing, soil treatment, crop rotation practices, use of fungal and pest resistant crop varieties, and application of effective fungicides and pesticides. Practices should also include biological control measures for fungal and pest management. Digital platform modules can guide the farmer with integrated weather forecasting systems and modelling approaches to predict mycotoxin occurrence in raw material production.

Post-harvest and storage management

2 critical requirements for protecting ingredients post-harvest and during storage include accurate monitoring of mycotoxin contamination after harvest and using automatic spectral imaging technology to separate contaminated grains and other products before storage. The storage support system should include preservation treatments using mould control agents in liquid (preferable) or powder form, and automated real-time monitoring of temperature, relative humidity, and carbon dioxide levels in silos as risk level monitoring markers.

Innovative pre-milling and milling strategies are equally important for controlling mycotoxins. De-branning and micro-ionisation are the 2 major strategies for minimising mycotoxin contamination. Separating bran and other by-products effectively minimises mycotoxin contamination in milled products produced for human consumption. Milling by-products are often used in feed, creating a greater risk of mycotoxin contamination. A clear mycotoxin monitoring strategy with stringent quality control measures is necessary whenever by-products are intended for use in feed production.

Mycotoxin data management

An effective monitoring system, optimal mycotoxin analysis and data management are essential to map mycotoxin levels in different RM and finished products. Monitoring and analysis needs to be applied to local and imported RM. A country using both domestic and imported RM often faces a bigger mycotoxin challenge as multiple mycotoxins interact. As feed millers and integrators must decide quickly whether to accept or reject RM, an ELISA based mycotoxin analysis tool is necessary. Although analysing as many mycotoxins as possible will enhance understanding of total toxicity on animals, analysis for the “Big 6” mycotoxins (aflatoxins, ochratoxin A, DON, T-2 toxin, zearalenone and fumonisin B1) is considered sufficient for quality control purposes. A mycotoxin analysis strategy needs to be refined to limit contaminated raw materials so that their usage will not violate the laws of the region or detrimentally affect livestock health or performance.

Trouw Nutrition in its endeavour of feeding the future has developed efficient mycotoxin risk management strategies for use at the feed mill and on the farm. Mycotoxin management monitoring is carried out using a global network of Mycomaster rapid mycotoxin monitoring tools (see main image). This network informs a database that serves as a surveillance tool providing real-time information on mycotoxin situations (specific mycotoxins and their prevalence) around the globe. It also offers risk assessment for various species through Trouw Nutrition’s digital platforms like NutriOpt Mycotoxin Monitor and NutriOpt Mycotoxin Adviser. Mycotoxin Monitor provides a country-specific mycotoxin profile for RM and feeds, various species risk assessments, and potential solutions. Mycotoxin Adviser offers customised advice to livestock producers on their own feeds and RM.

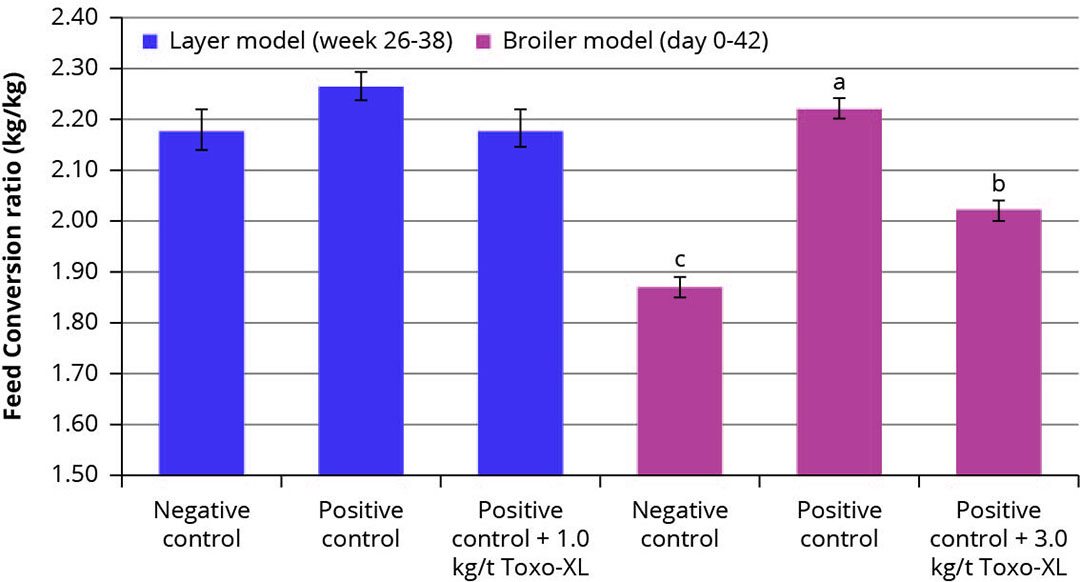

Figure 1 – Toxo-XL efficacy against multiple mycotoxins in recent in vivo studies.

Feed mill management

Auditing the feed mill to manage hygiene is critical. To keep mycotoxins at bay, mould growth should be avoided across feed production phases, especially in silos, mixers, elevators, and pellet coolers. Including mycotoxin binders in complete feed is a practical and effective management practice. However, as the structure and polarity of mycotoxins differ, relying only on mycotoxin binding strategy will not address challenges posed by multiple mycotoxins. Trouw Nutrition developed Toxo-XL to address the complexities that arise from managing multiple mycotoxins. Toxo-XL uses three modes of action to manage multiple mycotoxins. Recent in vivo studies conducted in broilers and layers have shown this innovation delivers excellent efficacy against multiple mycotoxins (Figure 1). In studies, the return on investment (ROI) for Toxo-XL inclusion was around 4:1. Research also proves that beyond mycotoxin binding, technologies to improve animals’ intestinal integrity and immunity should be included as part of a holistic solution to multiple mycotoxins.