Swiss dairy: Youngstock in the meadows and a focus on team work

Peter and Mathias Suter’s cubicle barn from 2000 has a somewhat unusual setup. In front of the barn, an 8-metre-wide strip has slatted floors over the full width. There are also slatted floors over the full length of the side walls, approximately 4 metres wide. The cows have continuous free access to this area.

“Following a referendum in 1991, outdoor access was made compulsory for all production animals, including dairy cows in the winter period,” explains Peter Suter. “The requirement is at least 10 metres of surface per dairy cow, 4 of which without a roof. This was the easiest solution in our case.” The waiting area at the milking parlour, which is 70 metres from the cubicle barn, also counts towards the required outdoor area.

Peter, together with his wife Helen, started the company in 1992 with 13 hectares, 80,000 kgs of milk quota and 15 sows. “We were able to grow through cooperation, good results and successful investments.” He now milks 140 cows on 63 hectares in partnership with his son and daughter-in-law, has 4,000 hens at a second location and is also an energy supplier. The solar panels on the stables supply about 300 mWh per year.

Highlighting ‘the team’ on the dairy farm

It is not surprising that he mentions collaboration first. He emphasises time and time again that ‘the team’ is the most important thing. The cooperation and teamwork already starts with land use. Of the 63 hectares, only the 6 hectares around the site are owned. The rest of the land is remote. 17 hectares have been leased from the owner of the poultry house that Peter and Mathias operate. The owner is in the cooperation with them and takes care of the hens. “We work as a team, only then can the cooperation continue.”

There is also cooperation in the lease of land from private individuals, former farmers. “In Switzerland you are only allowed to buy or inherit land – including that from family – if you have successfully completed at least 3 years of agricultural education and have a minimum farm size of 0.25 full-fledged workers.

Land is still mostly traded in the family in the flat dairy area west of Basel. It yields about €100,000 per hectare. “When selling to third parties, it goes for 4-5 times as much.” He points to a farm in the area with 800 fattening pigs on 25 hectares, which is for sale at a price of €20 million, and, according to Peter, there are serious buyers around.

Banks finance the purchase of land for a maximum of 80%, while 20% must come from their own resources. The lease price for agricultural land is relatively low given the market value: around €1,000 per hectare per year. “So it is much better to lease than buy if you want to grow in size. We have always focused investing in buildings and increasing production, and leasing added acreage.”

Suter doesn’t just lease production land. Of the 63 hectares, 45 hectares are on which he can spread manure. Manure is not allowed on the 10 hectares of nature land. That is reed land from which a cut of grass may also be harvested after 15 September. The short-cut reed is used by the dairy farmer for spreading litter in the cubicles. Manure is also not allowed on the 8 hectares of reed land. That nature land brings 2 cuts of hay after 15 June. “It mainly generates a lot of goodwill from citizens and, in addition, working on biodiversity is one of the requirements of the Greenmilk Swiss quality mark.”

Grazing cows

Because there is only 8 hectares around the cubicle barn, grazing is only possible to a limited extent. Suter grazes his cows for 2 hours a day for at least 26 days a month from April to October. This qualifies the farmer under Greenmilk Swiss for a surcharge of 3 cents on the milk price. With full grazing, an additional 5 cents is added, but then the average production may not exceed 8,000 kgs. “Not interesting for us. We don’t have enough house plot to graze much more and we are well above the 8,000 kgs.” Another requirement is that at least 25% of the dry matter intake comes from grass or grass silage.

The growing season in northern Switzerland runs from May to October where there is typically about 1,100 mm of rain per year. The clay soil is well drained. Groundwater is at a depth of 1m, and drought is not an issue here. Grass just about bursts out of the ground. The yield is about 16 tonnes dry matter per hectare per year, despite the limited fertilisation. The legal limit is 135 kgs of nitrogen, whether from animal manure or from fertilizer. A federal income support of €900 per hectare applies to maize and arable land, and €450 per hectare for grassland.

The effective area of 45 hectares of agriculture – 27 hectares of grass, 12 hectares of maize and 6 hectares of wheat to meet the subsidy conditions for greening – is not enough to provide the cows with sufficient roughage. That is why Suter buys 10 hectares of standing maize for silage every year at €3,000 per hectare with a yield of about 17 tonnes dry matter. He also buys 15 hectares of first cut grass silage at 400 euros/hectare.

Youngstock rearing in Alpine meadows

Suter reduces roughage consumption by outsourcing the rearing of youngstock. The young cattle run in the mountain pastures in the summer. “We continuously have about 70 head of youngstock from 4-24 months with 5-6 farmers in the mountain region. That costs €130 per month. The alpine air and the many herbs in the Alpine meadows have a positive effect, and we really notice very good health and see compensatory growth when they come back to our farm and get into milk.”

They take care of the transport themselves. It usually is by tractor, which takes 2 hours. If only 1 heifer needs to come back, they take the car and it costs an hour less. “The communication with the farmers is vital.”

Working in Swiss agriculture

A total of 10 people work on the farms: the entrepreneurs and their wives, 2 permanent employees and 2 on-call workers as well as 2 trainees. This brings the total to 4.5 FTE – 1 FTE in Swiss agriculture means working 50-55 hours a week. On average, Suter pays around €21 per hour for work. “Here too, the team feeling is the most important. People should enjoy working. After all, we are very dependent on our employees to keep the farm running.”

With 2,500 small enterprises in his region, the Swiss took second place as ‘best entrepreneur’ in 2022. “The first dairy farmer ever to receive such recognition,” he says with pride.

He also works on good PR. For example, he is an ambassador for dairy company Emmi.

Organic milk

Suter notices an increasing trend towards small-scale and organic in Switzerland. “Actually, politicians want milk from the mountains, the ‘Heidi’ feeling. That image is good for advertising, but it does not suit our company.” The main restraint for this is the drop in production, which Suter estimates at 30-40% due to the requirements for concentrate and maize use.

“You can then feed to a maximum of 5% of the dry matter from concentrates, a maximum of 20% from corn and concentrates together. The shrinkage of the milk output by far outweighs the better milk price and lower feed costs. But we are certainly not negative about organic; we will continue to monitor this.”

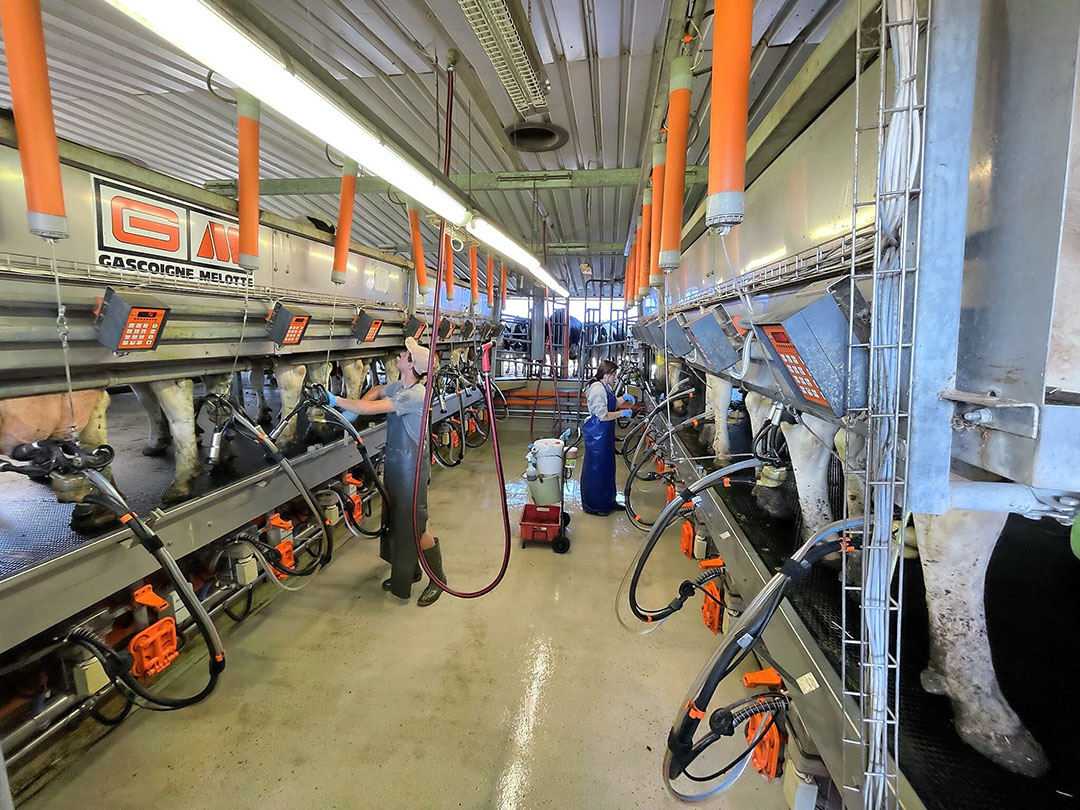

Milking parlour

The current 2×8 rapid exit parlour is 20 years old. It still suffices, but will require a major update within a few years. Switching to milking robots, a rotary milking parlour or a slightly larger milking parlour are all on the table. The final choice partly depends on the further steps in the company set-up.

The entrepreneurs are also exploring various options for this. The first is further steady growth towards 180 dairy cows. This requires at least an extra trench silo, replacement housing for the calves and additional purchase of feed; manageable costs. Peter leaving the company is a concern to son Matthias, mainly because of the loss of knowledge, experience and labour.

Manure disposal, solar panels and biogas

Manure disposal is also an item with an increase in scale. The company now has to deliver half of its cattle slurry to third parties mostly with no payment. The costs are not too bad by Dutch standards: €8 cubic metre. “Manure disposal costs in this region are the highest in the country due to the high density of pigs.”

A second option is to invest in more solar panels. The Suters estimate the costs for 450 mWh capacity at around €1.4 million because stable and roof space must also be set for it. “A solar field is not allowed, otherwise we would have opted for it.” This investment clearly fits best in terms of work and also fits in well with Matthias’ background. He is trained as an electrical engineer.

The third option is investing in biogas. This could be a mono-digester for their own manure, capacity 50kW, yield about 350 mWh. A digester with double capacity in cooperation with the neighbouring farm is also an option, as well as a digester for all companies within a radius of approximately 2 km. That should be 400kW. “Green energy is leading in Switzerland. The prospects for biogas subsidies are not clear; the current schemes will end in 2025.”

Peter has a clear preference for steady growth towards more cows, which means building on existing processes. His son Matthias keeps the boat a little more afloat in that respect. But during a tour of the stables, he indicates that more cows are the best option financially and structurally. “It probably will turn out that way.”

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.