Health and well-being paramount on Finnish pig farm

Finnish pig farmer Taru Antikainen works animal-oriented to produce healthy pigs with intact tails. She receives a premium for the pigs that are raised without antibiotics.

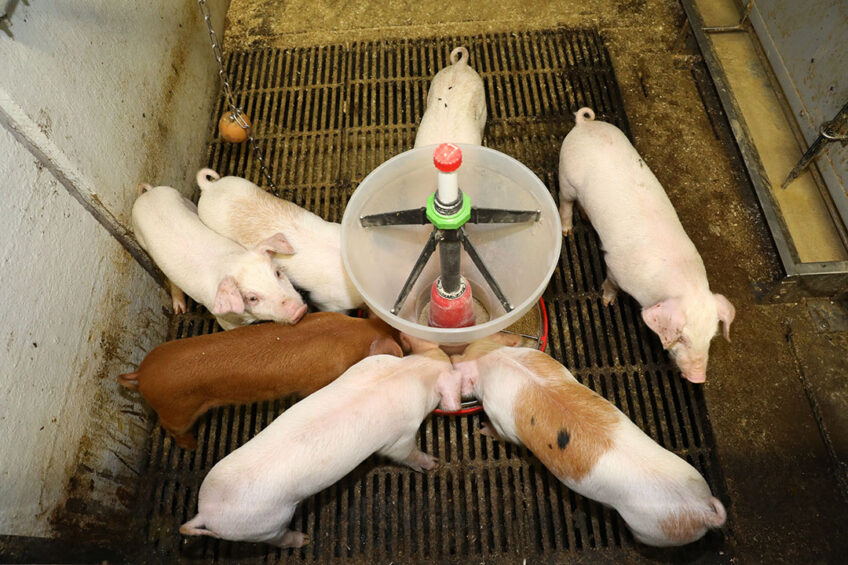

Animal welfare is always top of mind on Finnish pig farms. This is no different at Taru Antikainen’s farm. The weaned piglets have sawdust on the largely closed floor and play material hangs from the pen partition. The pens are spacious and have a long trough where all the animals can eat at the same time. Finns often work with climate zones in the compartments. A warm area for sleeping and a cooler zone where animals can feed and fatten up.

A good, constant feed intake is important to prevent tail biting. Gut health must be in order and pigs must not feel hungry at any time.”

Stress-free space

This barn design was not chosen lightly. The Finns have not been allowed to tail dock since 2003. The pen layout, nutrition and climate are therefore fully designed to provide the pigs with a pleasant, stress-free space that does not encourage biting. The newly weaned piglets even have a feeder in the pen to offer the animals dry food in addition to liquid feed. This contributes to the most relaxed weaning period possible, while the burden on the intestines is minimal. Taru Antikainen: “A good, constant feed intake is important to prevent tail biting. Gut health must be in order and pigs must not feel hungry at any time.”

Piglets observation

The pig farmer does her utmost to offer the best care possible for the piglets. She also spends a lot of time observing the animals. Keeping pigs with intact tails also means paying close attention to how the animals behave. If the tail is nicely curled and a pig has a full belly, the risk that it will bite is minimal. Antikainen points out the tails of piglets as she likes them, nicely curled and cheerfully moving back and forth. A piglet whose tail hangs down poses a risk of biting. The experience is that it is often the smaller animals, often also gilts, that start tail biting.

The pigs of a Duroc boar are fed rapeseed oil in their feed. The Finns also call them ‘omega 3 pigs’ because their meat contains more healthier fatty acids than conventional pigs, is the explanation. According to the farmer, the meat of her pigs is more tender and has a softer taste. Antikainen says “the fat composition of the pork is comparable to that of poultry meat.”

Antibiotics free

The pigs are grown without antibiotics. About 10% of the pigs still need to be medicated at some point. In 8 out of 10 cases that an animal receives antibiotics treatment is in the farrowing pen. The cause is mainly diarrhoea or inflammation. Treated animals are ear tagged and HKScan processes them as normal pigs. The pig farmer receives a premium for the pigs that are raised without antibiotics. The Finnish pig price is fairly stable and is less susceptible to market fluctuations.

Good health

The Finnish pig herd is PRRS and mycoplasma free. Good animal health is reflected in excellent technical results. The pigs on the farm of the Antikainen family grow 970 grams, while they are relatively light at processing. In the barn, there are hardly any coughing pigs because two major respiratory diseases play no part here. Moreover, it is cool in the stables. Manure cooling is used, this limits the formation of ammonia in the manure well.

Completely Salmonella free

Another point is that the pig herd is completely Salmonella-free. Finland has a zero tolerance policy for Salmonella, just like neighbouring Sweden. If a shed tests positive for salmonella, it will be cleared. The insurance covers the damage, but the first six months after starting up with new animals is at the risk of the pig farmers.

Keeping pigs Salmonella-free requires strict entry controls on the feed. This is because feed poses the greatest risk of introduction. The Finns do little to import feed or raw materials; the farms produce much of the feedstuffs on their own land. This year 150 hectares of summer barley was sown, which is the main ingredient in the feed. In addition, wheat, black beans, rapeseed and hay are grown. The ration is also supplemented with field beans and by-products from the alcohol and dairy industry.

However, the Finnish feed sector is not overflowing with nutritional knowledge, says business advisor Jan Vugts of meat processor HKScan. That lack of knowledge is becoming increasingly problematic. The highly productive sows on the farm need good feed. With 17.7 piglets born per litter, a lot is required of the sows.

Preparing pigs for slaughter

Preparing the pigs for slaughter takes place in 3 stages. The animals stay up to 40 kg in the piglet shed. After weaning, the litters stay together as much as possible. In the range of 40 to 70 kg, the pigs are placed in ten’s. In the fattening phase, the animals are again in another section where they are together (around 6 or 7 pigs together). The extra move will be done to make the best possible use of the space. A compartment for fattening pigs is emptied in 2 deliveries to the processors.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.