Proactive versus reactive mycotoxin risk management

Mycotoxin risk management requires a multi-pronged approach to manage the various factors involved. Despite the benefits of various proactive strategies, some discussions have focused on reactive measures. The pros and cons of both ways are discussed in this article.

MYCOTOXIN SPECIAL 2023 – read all articles

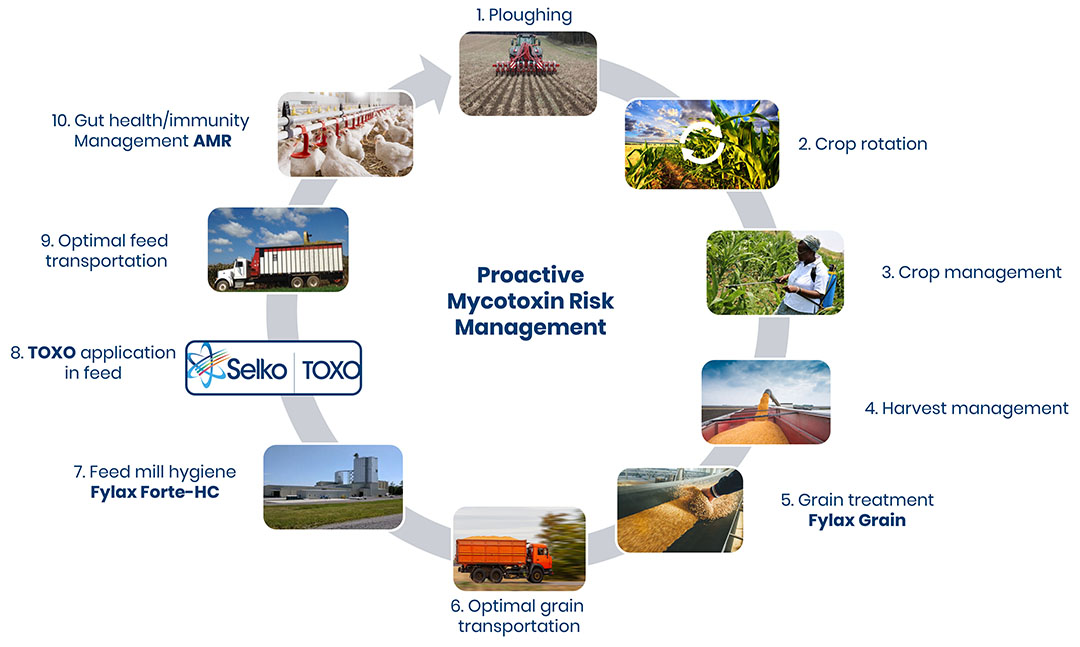

More than 600 mycotoxins have been chemically identified and that number is increasing every year. The global animal industry has acknowledged that the adverse economic effects mycotoxins have on raw material quality, feed quality and animal production are enormous. It is also accepted that mycotoxin risk management is an integrated approach involving diverse factors responsible for mycotoxin production and this should be the standard for managing mycotoxin risk (Figure 1). Climate change, improper agricultural practises, poor soil conditions, ineffective fungicides, and poor-quality seeds certainly increase crops’ susceptibility to moulds infestation in the field and consequent mycotoxin production. Unexpected rains have disrupted harvesting processes leading to increased moisture in raw materials and more mycotoxin production. If raw material transport and storage conditions are not ideal, mycotoxin production can continue.

Figure 1- Selko’s 10-point system for proactive mycotoxin risk management.

Proactive approach

Multiple factors influencing mycotoxin production suggest that mycotoxin risk management should be proactive during crop production and harvesting. Climate change can be minimised by following sustainable production practices. Crop rotation and tilling help to minimise mould growth in the field. Mono cropping and no-till production are both proven to increase mould growth and mycotoxin production. Drought conditions are known to increase mould growth, especially Aspergillus. The effects of drought can be reduced by timely irrigation of land. Unexpected rainfall during harvesting can increase mycotoxin production and having the facilities for optimal drying can reduce this impact.

Global trade also presents mycotoxin risk. Countries like Japan and Philippines import raw materials from USA, Argentina, Brazil, Canada, and Ukraine. Raw materials may be in transit for months and if conditions are not optimal, mycotoxin production is inevitable. Proactive measures, like making sure that raw materials are properly dried before loading helps reduce mould growth. Upon arrival at the grain warehouse/feed mill, raw materials need to be stored properly. Spraying liquid mould inhibitors (Selko Fylax Grain) on raw materials can help to reduce mould growth. Insect damage, rodent activity and dust accumulation must be controlled for effective feed mill management. The main areas in a feed mill where higher mould growth occurs include silos, mixers, coolers, and elevators. Regular cleaning of such locations has proven to reduce mould growth and mycotoxin production. Maintaining a mould count below 500,000 CFU per gram in raw materials and feeds is recommended. Feed produced using good quality raw materials can be re-contaminated with moulds and mycotoxins if not stored properly. Good feed storage practices in feed mills and farms minimise mycotoxin risk. If feed will be stored for more than a week, using mould inhibitors in the feed (Fylax Forte-SP) is advised.

Analysis up front

While moulds that produce mycotoxins may be visible, mycotoxins are invisible and can only be confirmed via analysis. Mycotoxin analysis in raw materials and feeds is the most proactive approach to understand mycotoxin risk. There have been tremendous developments in mycotoxin analysis starting from TLC to ELISA to LC-MS/MS. Rapid mycotoxin analysis (Mycomaster), in raw materials particularly, helps feed millers and integrators make informed decisions on accepting or rejecting raw materials. Mycotoxin analysis of complete feed can explain unexpected performance and health issues noticed in livestock and poultry. Sampling error is the biggest challenge associated with such mycotoxin analysis but a lack of information available on masked mycotoxins also challenges analysis and interpretation.

Reactive approach

Recognising the sampling error issues associated with mycotoxin analysis in feeds, some organisations started analysing mycotoxins in the blood of exposed animals. This is a good example of a reactive approach to mycotoxin risk management. Although blood analysis can indicate the potential exposure of animals to mycotoxins through the feed, it will not help prevent the risk as the animals have already been exposed to mycotoxins and may have suffered toxicity. On top of this, a specific mycotoxin undergoes extensive Phase 1 and Phase 2 detoxification in the body, leading to a number of mycotoxin metabolites. It is practically impossible to measure all metabolites to arrive at an animal’s quantitative mycotoxin exposure risk. Blood analysis of mycotoxins may be used as a veterinary diagnostic tool but not as a proactive means of managing mycotoxin risk.

Binding as insurance

Using mycotoxin binders (Selko Toxo product range) as insurance against potential mycotoxin threats is an example of proactive mycotoxin risk management. Since moulds and mycotoxins are ubiquitous in nature, it is wise to assume that animal feeds will contain mycotoxins and use a mycotoxin binder as an insurance. Taking a proactive mycotoxin risk management stance can help protect crops, feeds, animals and humans and advance safety across the food chain.

Join 13,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the dairy sector, two times a week.