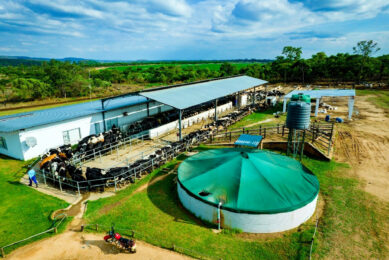

Exploring the challenges of running a dairy farm in Nigeria

Running a dairy farm in Africa – in Nigeria to be exact – can certainly be a challenge both terms of the environment and security. But at our 500-cow farm in Kaduna state in northern Nigeria, one of our biggest challenges is getting the right people to work on the farm.

After having worked in advisory services for Chinese farmers for 3 years, where milk production is still developing but well on the way to success, the transition to Nigeria was a bigger task than expected when it came to the matter of hiring people with the right skills. You might not expect that to be the case in a country the size of Germany and France, and a population the size of Germany, France and Italy combined. But this is a fact.

The main reason comes simply from the fact that there are only a handful of advanced dairy farms in the country, so even if people would want to learn how to work on a modern dairy farm, that is simply not possible in Nigeria. This led to the biggest challenge I have come across in 30 years of working with dairy farming issues around the world.

The first task was to hire a farm manager and here I wanted to have an experienced veterinary that has worked with cattle, especially because we planned to bring in heifers from Denmark to this completely new land for them, with many known diseases we have not seen or had in Europe for decades. We had to make sure we had good veterinary services from day 1, with good vaccination programmes, etc. This was thankfully a good decision and we have not had any disease outbreaks or pandemic diseases like Foot and Mouth Disease, Lumpy Skin Disease, etc.

Dairy farm manager

After hiring a farm manager, we focused on hiring people with some cattle experience and some education within agriculture. But everything was new for the employees, like dealing with Holstein cattle that are nearly 3 times bigger than the local breed. Milking with milking machines was also alien to all of them. To solve this we held many training sessions, where we go into detail over work practices and then, with manually monitoring the work routines and practices, the employees learned how to do the work.

Fewer dairy heifers

But that is of course not the whole story because when the experience is not there, the reaction to changes or deviation from what is normal is not there either. When we imported heifers to the farm from Denmark, we decided to only bring in one batch of heifers – a full plane of heifers. That meant that our farm, which is designed for 500 milking cows, only started up with a bit over 200 heifers. This was essential to success, as the number of animals was fewer than if we would fill up the farm from day 1. We have had time to adapt to the work routines and, at the same time, teach employees how to cope with different situations.

I always tell dairy farmers that nobody expects them to be experts in all matters that are related to dairy farming, and the same goes for the advisers that give advice to dairy farmers. Even with my experience in dairy farm management that spans decades, I still do not advise on certain topics.

Experts at the dairy farm

Because of this we have hired in experts to help out in some specific fields of dairy farming so our Nigerian dairy farm has an even better chance of greater success. For breeding advice, mating plans etc. we rely on experts from the Nordic breeding company VikingGenetics, while for feed advisory and TMR recipes we get advice services from the Danish dairy advisory company DGK, and for specific veterinary issues we also rely on Danish experts in the field. All this is done to secure the right support and service for the operation.

Now, after having had animals at the dairy farm for just over a year, we are slowly moving into Standard Operating Process (SOP) management practices to improve efficiency and effectiveness (LEAN) processes on the farm. The employees have the routines in place and have developed a lot in only 12 months. Now they are at the right place to take the routine to the next level, to make the work even more systematic and robust. I have said here before, in a previous article, that “if it’s boring for us, it’s better for the cows” and I truly mean that. By making our day on the dairy farm as uniform as possible, we increase our success rate, and that’s what it is all about!